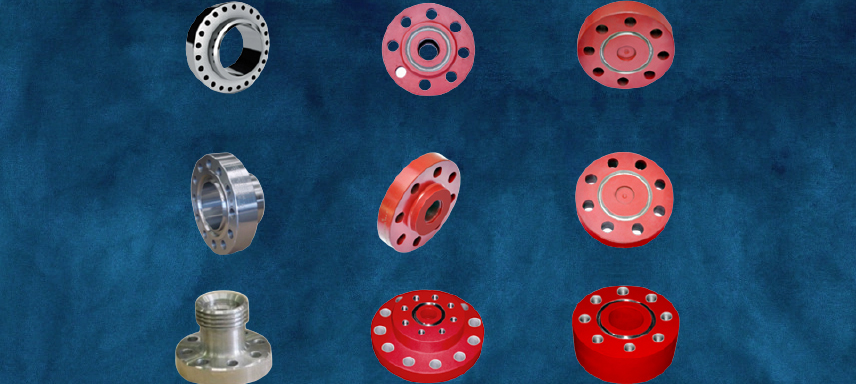

BX and 6BX flanges (welding neck flanges, blind flanges, target flanges) provided by CCSC are field proven flanges which strictly designed and manufactured according to API 6A and API Spec Q1 forged or casted.All kind of flanges are delimited by API 6A as below:

Welding neck flange is the flange with a neck on the side opposite the sealing face prepared with a bevel to weld to corresponding pipe or transition pieces.

Threaded flange is the flange having a sealing face on one side and a female thread on the other for the purpose of joining flanged connections to threaded connections.

Blind flange is the flange with no center bore, used to close off completely a flanged end or outlet connection.

Target flange is a special configuration of blind flange used downstream, facing upstream, to cushion and reduce the erosive effect of high velocity abrasive fluid. This flange has a counter bore filled with lead.

6B flanges are of the ring joint type and are not designed for face-to-face make-up. The connection make-up bolting force reacts on the metallic ring gasket.

6BX flanges are of the ring joint type and designed with a raised face. Depending on the tolerances, the connection make-up bolting force may react on the raised face of the flange when the gasket has been properly seated. This support prevents damage to the flange or gasket from excessive bolt torque.

Features:

Can be used to connect with any combination of sizes and pressure ratings

Special Flanges are available to transition between API, ASME, MSS or other styles of flanges

Supplied with standard or customer specific lengths

Available for general service and sour service in compliance with any temperature rating and material requirements specified in API Specification 6A

Available with Inconel 625 corrosion resistant ring grooves.

BIC Industries Manufacture Flanges as per below Requirements: